Deadly Mistakes to Avoid in High-Rise Window Cleaning with Rope Access (2025 Guide)

Introduction: The Invisible Risk in Urban Heights

High-rise window cleaning with rope access is one of the most specialized, high-risk maintenance tasks in modern urban environments. In cities like Dubai, New York, and Singapore, where glass towers define the skyline, rope-access technicians are the unsung heroes who keep these architectural marvels shining.

However, behind this seemingly simple service lies an industry where a single mistake can cost lives — or destroy a company’s professional reputation.

Whether you’re a cleaning contractor, facilities manager, or building owner, understanding the mistakes you should never repeat in high-rise window cleaning can mean the difference between safe, profitable growth and catastrophic loss.

1. Ignoring Proper Rope Access Certification (IRATA / SPRAT)

The biggest mistake companies make in high-rise window cleaning is hiring untrained or uncertified technicians.

Global safety standards — like IRATA (Industrial Rope Access Trade Association) and SPRAT (Society of Professional Rope Access Technicians) — exist to ensure every worker knows how to handle vertical descent systems safely.

Without certification:

- You violate international safety regulations.

- Insurance may not cover accidents.

- You put workers and your business reputation at risk.

EEAT Insight: In the UAE and UK, IRATA Level 1 certification is now mandatory for all rope-access cleaning professionals. Clients increasingly demand proof before signing service contracts.

Must Read: Cleaning Business Tax Registration Guide

2. Using Low-Quality Ropes or Harness Systems

Your entire operation depends on the integrity of your rope system. A small compromise — like using a worn rope or substandard harness — can cause catastrophic accidents.

Common rope-related mistakes:

- Failing to check the load rating before use.

- Ignoring rope wear from UV exposure or chemical cleaning agents.

- Mixing ropes of different brands and materials.

Ropes used for high-rise cleaning should meet EN1891 Type A safety standards and undergo routine inspection logs every 6 months.

Professional Tip: Dubai Municipality’s building maintenance safety code now requires double-rope redundancy — one for suspension, one as backup — on all window cleaning operations.

3. Neglecting Weather & Wind Conditions

Weather is one of the most underestimated factors in rope access operations. Even a slight increase in wind speed (above 10–12 m/s) can make rope cleaning dangerously unstable.

Common weather-related mistakes include:

- Failing to monitor live wind data before ascent.

- Working in sandstorms or rain (especially common in Dubai’s coastal zones).

- Using chemical cleaners that react with high humidity.

Real Case: In 2025, a rope access cleaner in Doha was injured when strong gusts swung him into a building façade. The company faced fines for ignoring pre-job weather checks.

4. Skipping Anchor Point Testing

Anchor points are your life insurance. They carry the full weight of the worker and must be load-tested annually under EN795 standards.

A major mistake companies make is assuming anchor points are still safe from last year’s test or not maintaining proper documentation.

When anchor bolts corrode, loosen, or get replaced during renovations, they can fail without warning.

Anchor Testing Checklist (2025 update):

✅ Test every 12 months (Dubai standard)

✅ Label and record test ID visibly near anchor point

✅ Use only certified testing equipment

✅ Maintain digital reports for audits

Source: OSHA Fall Protection Standards

5. Poor Communication Between Cleaners and Ground Crew

In rope access window cleaning, communication equals safety. Lack of coordination between the suspended cleaner and the ground team leads to:

- Misjudged rope tension

- Dropped tools or cleaning equipment

- Delayed emergency responses

Many accidents occur because teams rely solely on shouting or hand signals in windy environments.

✅ Best practice (2025):

Use two-way radio headsets with noise cancellation, and establish emergency code words before every job.

Pro Tip: IRATA recommends assigning a “Safety Officer” per building to monitor all rope movements via binoculars and maintain direct radio contact.

6. Overlooking Chemical Safety in Cleaning Solutions

It’s common for cleaners to focus on rope safety but ignore the chemicals used for glass cleaning. Many detergents contain ammonia or solvents that can:

- Damage rope fibers (especially nylon).

- Release toxic fumes at height (no ventilation).

- Corrode façade coatings on aluminum or tinted glass.

Never mix different cleaning agents mid-job — always use pH-neutral, rope-safe solutions approved for high-rise applications.

Safety Note: 3M and Unger now offer certified rope-safe glass cleaning liquids that comply with Dubai Green Building Standards.

7. Underestimating Emergency Evacuation Procedures

Even the best-trained teams face emergencies — sudden illness, wind shear, or rope entanglement. Many companies skip real evacuation drills, thinking “it’ll never happen.”

That assumption is fatal.

Every rope-access cleaning firm must maintain:

- A written rescue plan on-site.

- Certified rescue equipment (descenders, haul systems).

- Trained standby rescuer on the roof, not on the ground.

Industry Insight: The 2024 IRATA Safety Report found 72% of recorded incidents were worsened by delayed rescue response — not initial rope failure.

8. Ignoring Legal Liability and Insurance Gaps

Without specialized rope access insurance, your company could lose everything in an accident claim. Many general cleaning insurance policies exclude “work at height” or rope-based operations.

Always confirm your policy includes:

- Rope access liability (at least $5M coverage)

- Worker injury compensation

- Third-party property damage

- Equipment and tool coverage

Must See: What Pollution Liability Means for Cleaning Services

Source: HSE Work-at-Height Regulations

9. Using Inadequate Equipment Maintenance Logs

If your company can’t produce a maintenance record for harnesses, ropes, or descenders, you risk immediate site suspension in Dubai or Singapore.

Every item must have:

- Serial number tracking

- Inspection date

- Inspector’s signature

Digitizing these logs using cloud software (like SafeWorkPro or InspectAll) is now standard across top-tier rope access firms.

10. Hiring Based on Cost, Not Competence

In Pakistan, many facility management firms try to “save money” by hiring unverified rope cleaners. The result?

- Poor glass quality

- Unsafe rigging

- Damaged cladding

Building owners often pay double when forced to rehire certified teams to fix mistakes.

EEAT Note: Always vet your subcontractor’s IRATA level, safety records, and liability insurance before granting site access.

Expert Advice: Safety Is the New Luxury

In 2025, rope access window cleaning is no longer just about clean glass — it’s about precision, professionalism, and prevention.

Companies that treat safety as a marketing advantage (not just a requirement) consistently attract premium international contracts.

11. Failing to Conduct Daily Pre-Job Safety Meetings (Toolbox Talks)

A small but critical mistake: skipping daily “toolbox talks” before rope-access operations.

Many teams assume yesterday’s briefing covers today’s work — but weather, personnel, or building conditions can change overnight.

A daily safety meeting (10–15 minutes) ensures every cleaner:

- Reviews the rescue plan.

- Verifies equipment condition.

- Confirms communication codes.

- Knows who the rescue standby is that day.

EEAT Tip: Companies like Al Fajer FM (Dubai) and ISS Facility Services (UK) now integrate digital “Toolbox Talk” checklists for traceable compliance.

12. Poor Rope Management and Cross-Line Entanglement

Rope entanglement is one of the most dangerous and completely preventable errors in high-rise window cleaning.

It often occurs when multiple technicians descend side by side without a rope path plan.

Common causes:

- Crossing suspension and safety lines.

- Dropping ropes onto sharp façade edges.

- Using the same anchor set for multiple workers.

✅ Best Practice:

- Assign rope lanes per technician.

- Use rope protectors over corners and ledges.

- Color-code ropes (blue for main, red for backup).

Case Study: In 2025, a Dubai Marina site halted operations after a cleaner’s rope snagged on a glass panel seam, forcing an emergency evacuation.

13. Overconfidence After Certification

Many newly certified IRATA Level 1 technicians develop overconfidence — forgetting that certification proves only minimum competence, not mastery.

This mindset often leads to:

- Ignoring instructions from supervisors.

- Attempting solo descents on complex façades.

- Taking shortcuts to “save time.”

Expert Insight: Rope access safety is cumulative — every descent builds muscle memory and judgment. Companies should mandate refresher training every 6 months, not yearly.

14. Ignoring Façade Material Compatibility

Different façade materials — glass, aluminum, or marble — require unique cleaning chemicals and techniques.

Mistake: Using a single cleaning formula across all surfaces.

This leads to:

- Chemical etching on glass.

- Fading or oxidation on aluminum.

- Staining on natural stone façades.

Solution: Always confirm the façade type in the project’s technical drawings before starting.

Pair this with manufacturer-approved cleaning agents only.

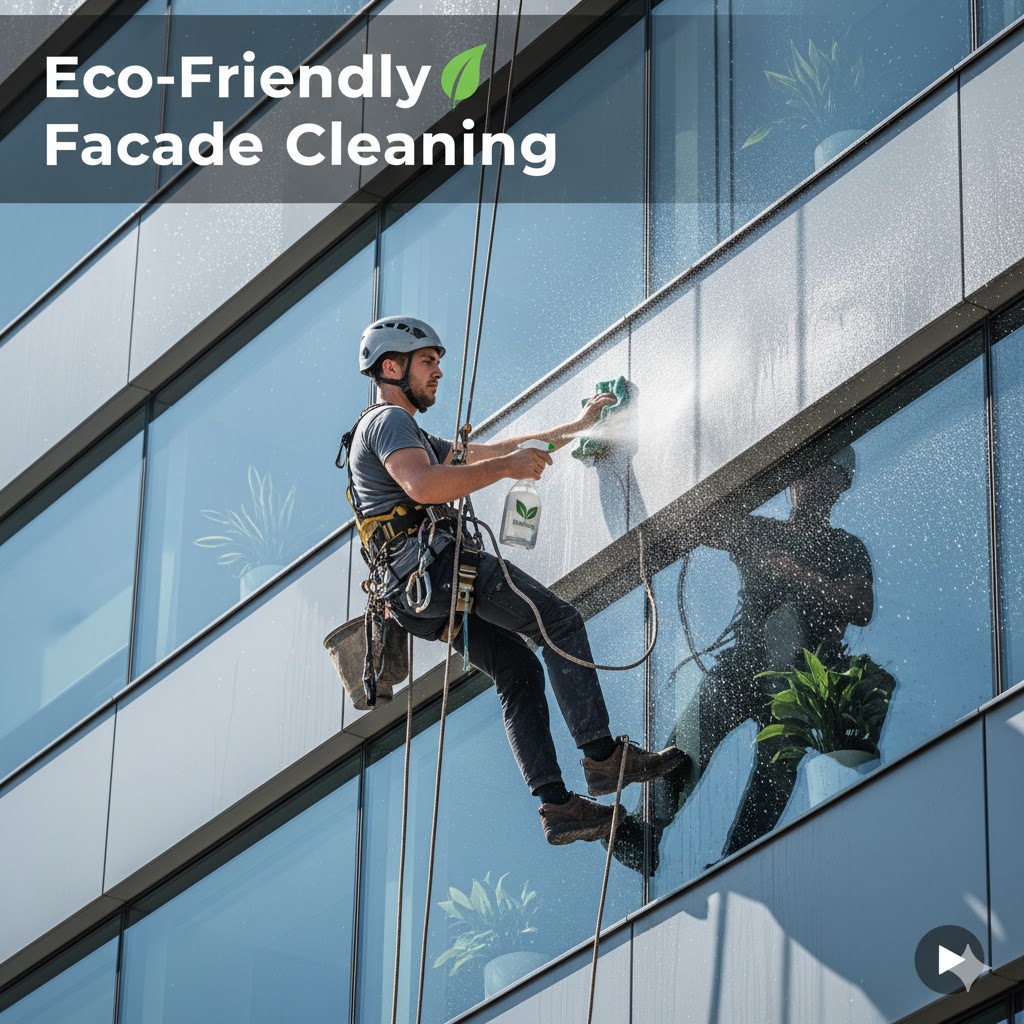

Eco Tip: Use biodegradable solutions like Unger’s Stingray System or Kärcher Professional Glass Cleaners to meet Dubai Green Building Regulations.

15. Neglecting Periodic Rope Replacement Schedules

Ropes are not lifetime assets — they degrade with UV light, dust, and chemical exposure.

Many small contractors, especially in developing markets, continue using ropes beyond the manufacturer’s lifespan.

Best Practice 2025:

- Replace every 6–12 months, regardless of visual condition.

- Record date of purchase and usage hours.

- Rotate ropes (training vs active duty).

Source: Petzl Rope Lifespan Guidelines

16. Lack of Proper Tool Lanyards and Drop Prevention

Dropped tools are among the top 5 causes of fatal injuries in rope access work.

A 250g squeegee can hit the ground at over 120 km/h from 40 floors up.

Every tool — even cloth wipes — must be tethered with lanyards.

Tool bags should be secured below the work line, not dangling freely.

Dubai Municipality Rule:

All rope access projects must have a “Dropped Object Prevention Plan (DOPP)” reviewed before work begins.

17. Using Inexperienced Supervisors

Supervisors who lack rope access field experience often make unsafe calls from the ground.

A proper supervisor must hold at least IRATA Level 3 certification and firsthand climbing experience.

Supervisor duties include:

- Visual rope inspections.

- Emergency oversight.

- Approving weather go/no-go decisions.

Professional Insight:

The UK’s BS 7985 Code of Practice mandates that only Level 3 Rope Access Technicians can manage works at height — a standard Dubai FM firms now mirror.

18. Failing to Maintain Audit-Ready Documentation

Audits are more than bureaucracy — they’re legal protection.

Without traceable records of:

- Equipment checks,

- Training certificates,

- Rescue drills,

- Anchor testing —

you cannot defend your company during safety investigations or insurance claims.

Digital audit tools like Formstack Safety or iAuditor streamline compliance while improving EEAT credibility for clients.

19. Ignoring the Economics of Rope Access

Many managers underestimate the ROI of professional rope access versus traditional scaffolding.

They assume rope work is costly — but in fact:

| Method | Setup Time | Cost per Project | Mobility | Risk Level |

|---|---|---|---|---|

| Rope Access | 1–2 hrs | 30–40% less | High | Moderate |

| Scaffolding | 2–3 days | High | Low | Low |

Business Tip: Smart contractors highlight rope access as “cost-efficient precision cleaning” in proposals — boosting client trust and perceived expertise.

20. Overlooking Future Innovations (Drones & Robotics)

The future of façade cleaning is hybrid — combining rope access with AI-assisted drones and robotic cleaning systems.

Rope + Drone Integration Advantages:

- Reduced human exposure.

- Faster façade assessments.

- Enhanced data for maintenance reports.

Dubai Expo 2025 projects are already testing AI drones to pre-clean façades before human crews descend.

Pro Insight: Early adopters of hybrid cleaning systems will dominate tenders as safety automation becomes a bid requirement.

Expert Review: Mastery Through Awareness

In rope access window cleaning, perfection equals survival.

Every mistake avoided is a life saved — and a reputation strengthened.

By embracing professional training, transparent audits, and technological upgrades, your firm becomes part of a new global safety standard — one built not just on clean façades, but on clean ethics and clean operations.

FAQs: High-Rise Window Cleaning with Rope Access

- What is rope access cleaning?

Rope access cleaning uses industrial climbing gear to safely clean or maintain building exteriors without scaffolding. - Is rope access safe?

Yes — when conducted under IRATA or SPRAT certification with redundant systems and rescue plans. - What height qualifies as “high-rise”?

Typically, any building above 35 meters or 12 floors. - How often should ropes be replaced?

Every 6–12 months, depending on wear and manufacturer guidelines. - Can rope cleaning be done in rain?

No. Wet ropes lose friction and increase descent speed dangerously. - Do you need a license in Dubai?

Yes — all rope access firms must register under Dubai Municipality FM Regulations. - What’s the average cost per square meter?

Roughly AED 3–5/m² in Dubai; varies by façade complexity. - Can rope cleaners work at night?

Yes, but only with proper façade lighting and municipal approval. - Are drones replacing rope cleaners?

Not yet — drones assist inspections but cannot perform manual scrubbing. - What happens if a rope fails mid-operation?

A secondary backup rope prevents the fall; rescue is immediate.

2 Comments